Scales, weighing

The company Dites-vahy spol. s r.o. (Ltd.) manufactures and supplies mainly technological loadcells scales , see below. Some types of technological scales can also be used for commercial weighing (bridge scales, flow scales, ..).

For very light materials, volumetric "scales" are used where, however, the height of the column of material in the container is measured.

The electrical output signal from the loadcell is proportional to the load of the weighed material (bulk materials, lump materials, liquids). The signal is further processed in the amplifier and fed to the evaluation device, the system. Depending on their type, parameters and purpose, materials are transported to the scales by means of feeders (screw, vibrating, belt, gravity, disruptors, etc.)

Emptying of the weighed material from the scales is also performed by various types of feeders, flaps, pneumatic transport, etc. The scales are also divided into automatic, semi-automatic and manual scales.

An important parameter is the accuracy of weighing. It is determined primarily by the used strain gauges and is usually 1000-3000 pieces from the full range, resp. for technological scales around 0.05%. Another and important data is the accuracy of material dosing, which has a dynamic character. The dynamic dosing accuracy is always lower than the static weighing accuracy. This accuracy is mainly influenced by the parameters of the used material feeder to the scale, the accuracy is weighed against the weighing speed. It is therefore necessary to choose an acceptable compromise. Therefore, the expertise and experience of the relevant designer, specialist staff, etc. is necessary and necessary.

The division of an amplifier or also of an apparatus (evaluation unit) is usually much higher than the accuracy of load cells, which is sometimes mistaken for the accuracy of weighing.

We distinguish weights:

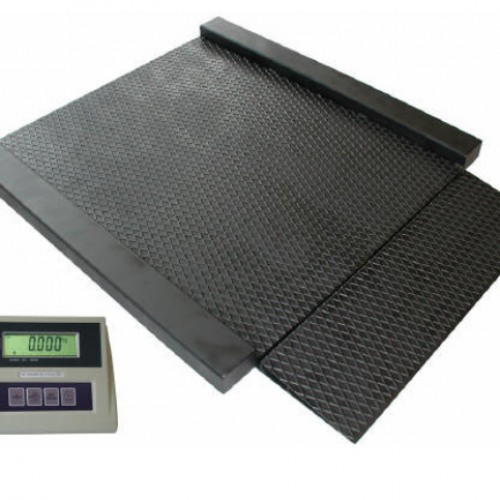

BIN SCALES / DISCONTINUOUS AND CONTINUOUS (FLOW) SCALES / BRIDGE SCALES / BAGGAGE SCALES / BIG-BAG SCALES / SPECIAL SCALES, etc .