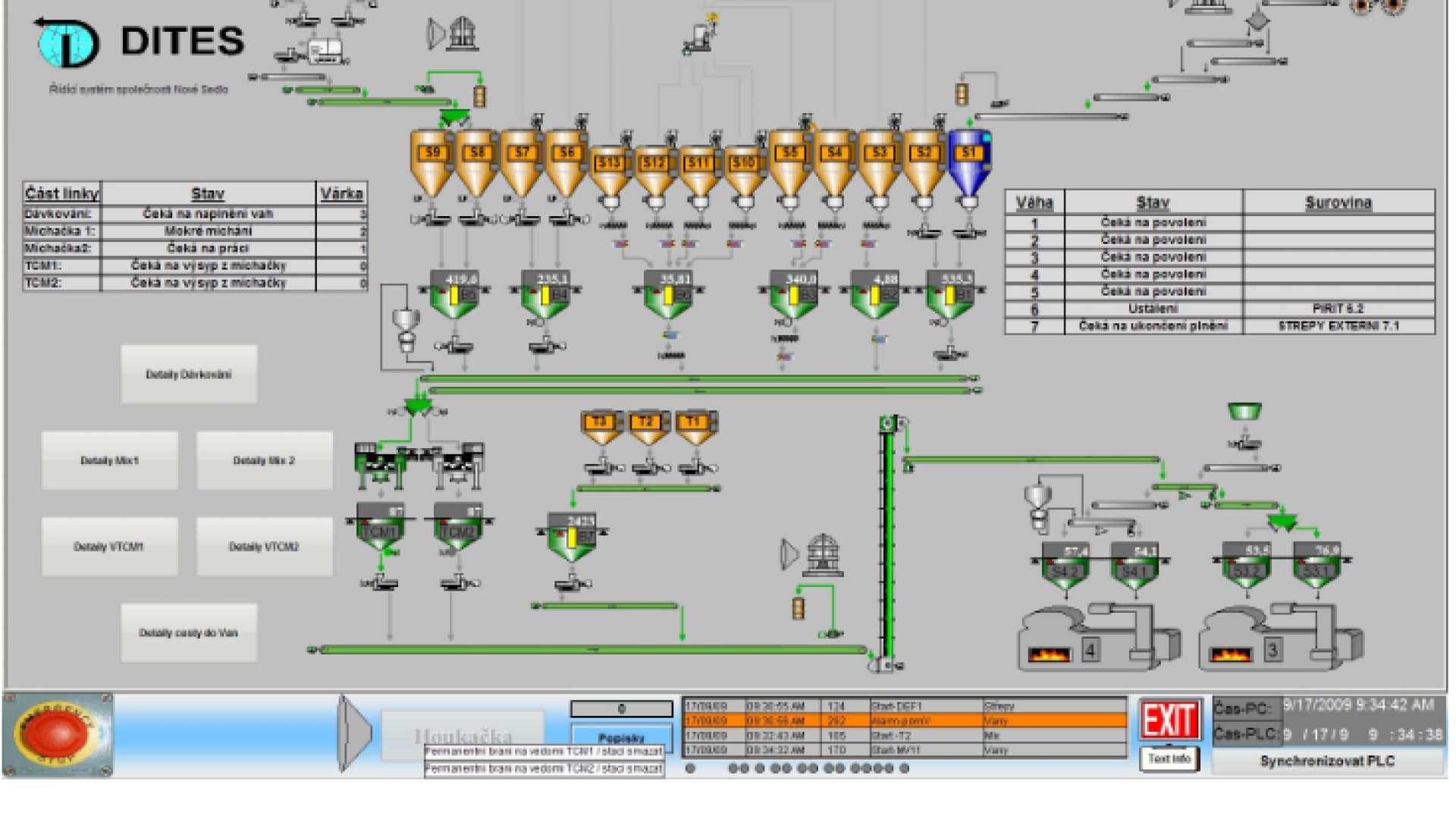

The control multi-user distributed system is operated with a commercial version of a PC for data visualization and archiving, a sequential PLC is used for control, which is located in the switchboard. There is usually a touch panel display on the cabinet door, which is used for local control.

Communication between the central PC unit, PLC, stations and other peripherals takes place via the industrial Ethernet network and the OPC server. The number of input and output signals that are digital, analog, etc. is almost unlimited. Various communication channels and interfaces are also available. If necessary, it is possible to expand and modify the system according to the specific needs of the customer.

The technology management system works in automatic mode or manual mode / service and emergency mode /. Accurate weighing / dosing / of material is ensured by controlling the speed of the feeders by frequency converters with the calculation of corrections and dynamics.

The technology is visualized on a PC with an LCD monitor. In addition to visualization of control, the user software also enables data storage in an archive with an SQL database, as well as calculation of balances, creation and modification of recipes, emergency manual control of individual machines, etc.

Visualization takes place under the CW system, / Control Web / or WinCC. Report output can be printed.

The solution meets all the requirements of modern management.

We will provide more specific and detailed information on request from subcontractors (eg from Dites spol. s r.o.)